Many eCommerce retailers are working with multiple distributors that can fulfill the same products. Each distributor has a different level of stock on hand, product price and other fulfillment fees.

Many eCommerce retailers are working with multiple distributors that can fulfill the same products. Each distributor has a different level of stock on hand, product price and other fulfillment fees.

In many cases retailers have an internal warehouse or 3PL where they can fulfill the same products from.

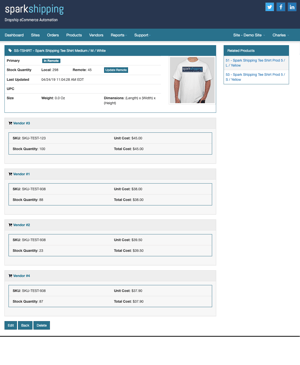

The trick to working with multiple supplier for the same product is that product data needs to be tracked at both the product and vendor level.

Here's the data you need to track

- SKU Mapping - The retail platform may be using 1 set of SKUs but each vendor may be using a different SKU, part number, UPC, etc. when sending inventory or receiving orders. You'll need to track all of these

- Product Vendor Stock - Each vendor is going to have a different stock level for each product so you'll want to track stock at both the vendor and product level

- Product Vendor Pricing - In the case of distributors, each will have a different unit cost for the same product. You'll need to be able to store the unit cost for multiple suppliers for each product.

- Vendor Costs - Each vendor will have additional fees (% or flat rate) that may be charged per order. These need to be stored at the vendor level but will be taken into consideration when deciding which vendor should receive the order fulfillment request.

The effectively route eCommerce orders to the lowest cost supplier you want to be sure all of this data is accurately updated and stored. As orders are received using intelligent order routing the order can then be routed to the lowest cost supplier.